For robotic system integration solutions designed for you, contact us today!

SprutCAM X Robot, an innovative all-in-one offline robot programming solution, speeds up complex and creative robotics tasks by multiples.

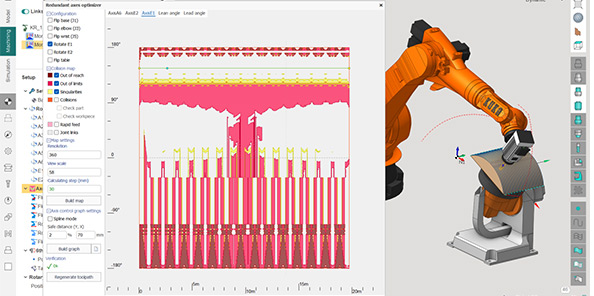

SprutCAM X Robot allows manufacturers and integrators to create an accurate real-world cell with equipment and production components in a virtual environment, as well as simulate all robot functions on the screen. The quality of simulation and detailing of digital twins in SprutCAM X Robot is second to none.

SprutCAM X Robot, an innovative all-in-one offline robot programming solution, speeds up complex and creative robotics tasks by multiples.

SprutCAM X Robot allows manufacturers and integrators to create an accurate real-world cell with equipment and production components in a virtual environment, as well as simulate all robot functions on the screen. The quality of simulation and detailing of digital twins in SprutCAM X Robot is second to none.