Home> Products > CNC Router > Nesting Cut > CNC router for nesting cut

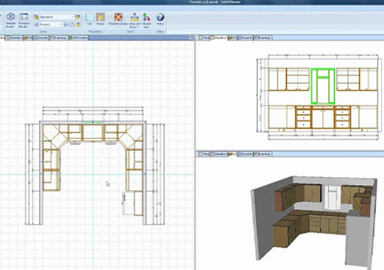

It is used in nested based production of cabinets, closets,wardrobe and custom furniture. Highly automated nesting solution with automatic loading and unloading system. The complete work cycle of loading, nest cutting, drilling and unloading is carried out automatically, which results in maximum productivity and zero down time. Truly versatile--nesting, routeing, vertical drilling and engraving all in one. It is well-suited for panel furniture, office furniture, cabinets production.

| Work area (mm) | 1300*2500 1500*3000 2000*3000 2000*4000 Other size |

| Spindle power (KW) | ATC: 9/12/15 |

| Tool Magazine | Carousel type |

| Capacity of Tool Magazine | 10/12 |

| Motor system | YASKAWA/SIEMENS |

| Auto loading and unloading | Yes |

| Controller | Taiwan SYNTEC / German SIEMENS / OSAI |

| Spindle RPM | 24000 rpm |

| Tool shank | ISO30/HSK 63F |

| Travel speed | 45-50mm/min |

| Repositioning Accuracy | ±0.003mm |

Specialising in CNC manufacturing for 15 years

Machine

lifetime over 10 years

Service response

time less than 1 hour

One-stop service including design, production, installation, training

Highest

cost-effective CNC solution

We have thorough CNC solutions for every industry, such as the industry of solid wood, chemical wood, plastic, ABS, PP/PE,GFRP, CFRP, ceramics, gypsum, stone, aluminum, nylon, etc.

Viewing the SolutionWe listed some common questions, you can find answers here quickly.